From the vacuum screw to the complete vacuum chamber.

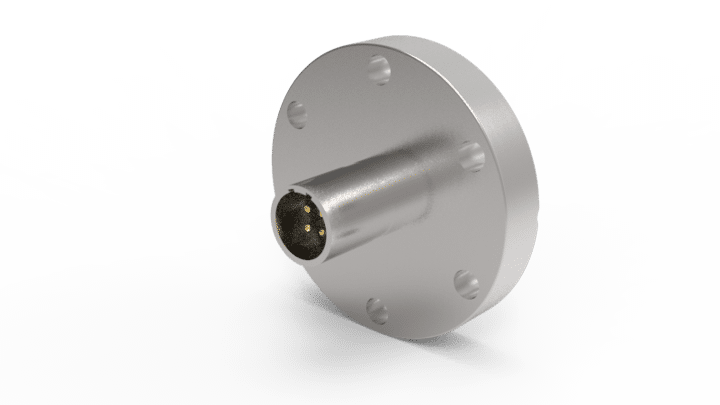

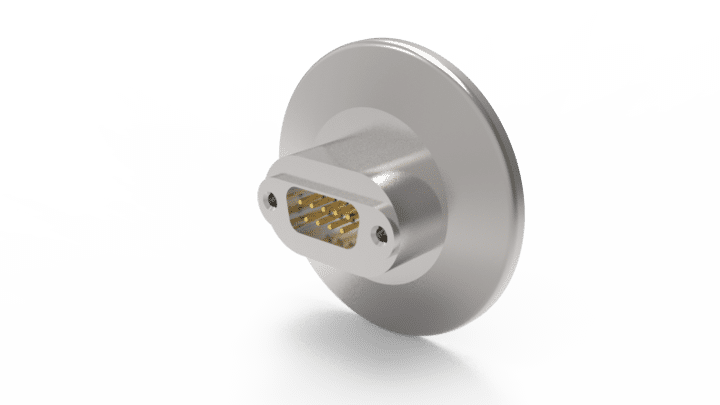

Electrical Feedthroughs

Electrical feedthroughs enable the transmission of electric power into or out of a vacuum chamber.

They consist of metal-to-glass-, metal-to-glass-ceramic- or metal-to-ceramic-compounds, whereas the dielectric component (glass, glass-ceramic or ceramic) electrically insulates the current loaded contacts from the metallic housing.

Besides the long-term stable hermeticity in high and ultra-high vacuum applications electrical feedthroughs often need to resist very high or cryogenic temperature. Also, the requirement for corrosion resistance against certain process media or for the use of non-magnetic materials is not unusual. Determined by a huge variety of possible applications a very large number of different feedthrough types are available for various operating conditions.

Multipin feedthroughs always contain at least two conductors and have a plug connection on the air side. Some feedthrough types provide a plug connection on the vacuum side as well. The related vacuum side plug connectors are exclusively made of vacuum suitable materials.

Multipin feedthroughs are ideally suited for a space saving transmission of multiple electrical signals into or out of a vacuum system for measurement & control applications.

The most important at a glance: | Our offer: |

|

|

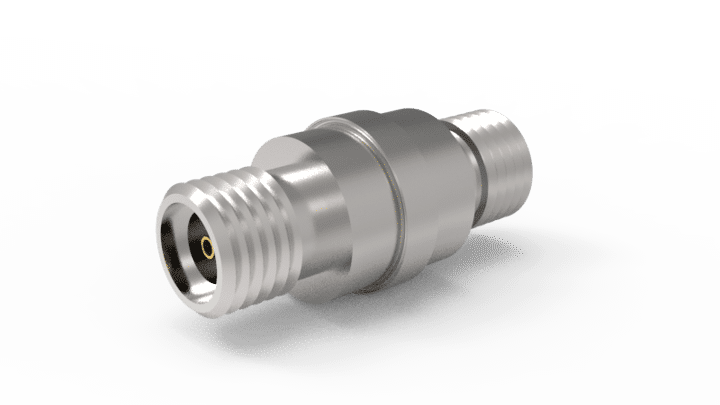

Coaxial feedthroughs are constructed of two concentric conductor paths, which are electrically insulated from each other by a dielectric material in between. The central inner conductor serves as a current carrying path, whereas the surrounding tubular outer conductor (“shield”) works as an electromagnetic shielding. In the majority of applications, the shield is at ground potential („grounded shield“).

Several coaxial feedthrough types are also available with a non-grounded (“floating“) shield. In addition, most types provide the option of 50 Ohm matched impedance to ensure a low-loss transmission of signals and data. Coaxial feedthroughs always have an air side plug connection for a standard coaxial connector. Additionally, most types are available with a double-ended plug connection.

Coaxial feedthroughs can be used universally, but in particular, they are applied for the low-loss transmission of RF signals with frequencies up to 40 GHz.

The most important at a glance: | Our offer: |

|

|

A triaxial cable – or in short „triax cable“ – is a special version of a coaxial cable. It consists of three concentric conductor paths, which are electrically insulated from each other by dielectic materials. The so-called “guard” is located between the central inner conductor and the outer conductor (“shield”) and serves as an additional shielding. It effectively improves the signal-to-noise ratio and supports the suppression of disruptive residual currents (“leakage currents”). Using a triax feedthrough the inner conductor and guard can be passed electrically insulated through a chamber wall, whereas the outer conductor of the feedthrough is electrically connected with the wall and therefore grounded.

Triaxial cables are suitable for the measurement of very small currents or signals and in some cases they are even mandatory.

| The most important at a glance: | Our offer: |

|

|

The appearance of these feedthrough types varies strongly depending on their technical specifications. High currents require large conductor diameters and materials with high electrical conductivity. High dielectric strength neccessary for applying high voltages can only be achieved by big ceramic insulating components providing long creepage distances between conductor(s) and housing. High Voltage and Power Feedthroughs are used for the transmission of high currents, high voltages or – in combination of both – high power in various vacuum applications.

The maximum transmittable voltage is 125 kV DC, whereas the maximum current rating is 1000 A. In addition, there are feedthroughs available specifically made for the input of RF power, e.g. for the RF generator frequency of 13.56 MHz.

| The most important at a glance: | Our offer: |

|

|

Thermocouple feedthroughs always contain conductor pairs. Each pair consists of two different materials due to the underlying measurement principle (thermoelectric effect, also “Seebeck effect”). The combination of materials depends on the common thermocouple types, which need to be connected to a thermocouple feedthrough, e.g. type K, E, J, T, N, R/S, C.

Matched to various application areas, thermocouples combine base metals, noble metals as well as metal alloys. Typical alloys are for example Alumel® (Nickel, Aluminum and Manganese), Chromel® (Nickel and Chromium) or Constantan® (Copper and Nickel).

Some thermocouple feedthroughs do not use the actual thermocouple material, but a so-called compensating material (“compensating wire”) instead. Compensating material is characterized by thermoelectric properties ideally adapted to the actual thermocouple material to be replaced. Also, it should be noted with these types that the temperature should not exceed 250°C ("maximum junction temperature 250°C") at the point of the vacuum side connection of a thermocouple.

Typical conductor material pairs with the corresponding type designation including the application area are listed in the following table:

| Thermocouple (ANSI designation) | Polarity | Measurable temperature range [°C] | |

| T | Copper / Constantan | + / - | -200 to 350 (-328 to 662°F) |

| K | Chromel® / Alumel® | + / - | 200 to 1250 (392 to 2282°F) |

| R/S | Platinum 13/10 % Rhodium* / Platinum* | + / - | 0 to 1450 (32 to 2642°F) |

| J | Iron / Constantan | + / - | 0 to 750 (32 to 1382°F) |

| E | Chromel® / Constantan | + / - | - 200 to 900 (-328 to 1652°F) |

| C** | Tungsten 5 % Rhenium* / Tungsten 26 % Thenium* | + / - | 0 to 2315 (32 to 4199°F) |

* using compensating wire; maximum junction temperature 250 °C (482°F)

** no ANSI designation

Thermocouple feedthroughs enable temperature measurements in vacuum processes. The temperature measurement is not carried out directly, but is calculated from the thermal voltage, which can be conducted from the chamber to an external measuring device by thermocouple feedthroughs.

| The most important at a glance: | Our offer: |

|

|

Isolators consist of an electrically non-conductive ceramic tube with metal sleeves soldered on both ends of the tube, which in turn are welded with vacuum flanges.

Isolators serve, inter alia, for the protection of ESD-sensitive devices in a vacuum chamber (ESD = electrostatic discharge). Also, they can be used as thermal barrier for the protection of temperature-sensitive components. In addition, isolators are used as pipelines for gases and liquids - especially in cryogenic technology - in hermetically sealed systems.

| The most important at a glance: |

|

VACOM offers a wide range of accessories for electrical feedthroughs like e.g. air side and vacuum side plug connectors, vacuum suitable clamps and crimp contacts, vacuum suitable cables, ceramic insulating elements, crimping tools, etc. Electrical feedthroughs and associated plug connectors (“plugs”) are always offered separately, if not explicitly declared otherwise. Connectors are always delivered including the ralated contacts (for soldering or crimping), if not explicitly declared otherwise. All accessory components serve for the electrical connection of electrical feedthroughs and integration into an overall system. Particular attention must be paid to the mechanical and electronic compatibility of the individual components (for example feedthrough, connectors, cables, electronic devices).

| The most important at a glance: | Our offer: |

|

|

Special electrical feedthroughs

Vacuum applications often require special components that are not available as standard on the market. We specialise in working with you to modify near-standard components or to develop, design and manufacture special components. Ask us, we will be happy to advise you.

Our core business – custom solutions: | Our offer: |

|

Contact us, we will be pleased to advise you! |