From the vacuum screw to the complete vacuum chamber.

Standard Components

VACOM's standard components include all components of vacuum systems that are necessary for the construction of chambers and vacuum lines, e.g. flanges, seals, pipe components (elbows, tees, crosses, etc.), vacuum chambers as well as moving elements. The use in vacuum technology places high demands on both the choice of materials and the manufacture of these components.

For different applications there are connection standards based on different flange systems. Therefore VACOM vacuum components are available in all important standards. Many components are available for use in clean rooms. These vacuum components are characterised by low particle contamination and generation. In UHV, XHV and UCV, low outgassing rates are required and proven.

Flange system | KF (ISO-KF) | ISO (ISO-K, ISO-F) | CF | QCF (Quick-CF) |

| Norminal size [mm] | DN10 to DN50 (3/8" to 2") | DN63 to DN630 (2 1/2" to 24") | DN10 to DN400 (3/8" to 16") | DN16 to DN100 (1/2" to 4") |

| Standard | DIN 28403 / ISO 2861 | DIN 28404 / ISO1609 | ISO 3669-2 | ISO 3669-2 |

| Continue to webshop | KF components | ISO components | CF components | QCF components |

Furthermore, we are specialised in manufacturing vacuum components according to your requirements

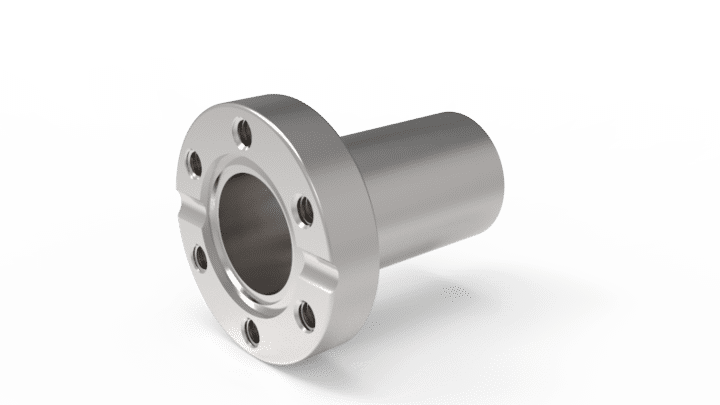

QCF components

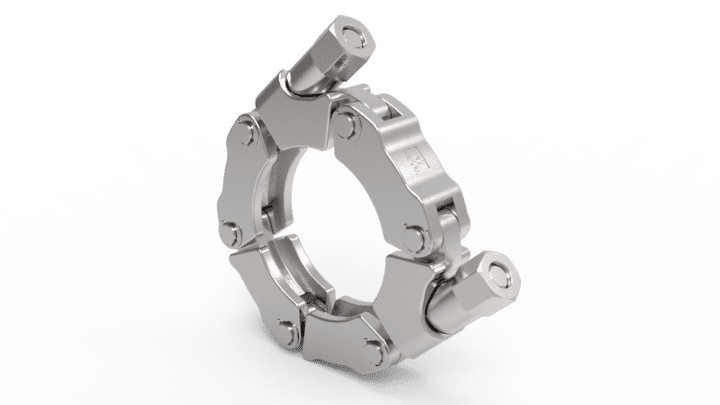

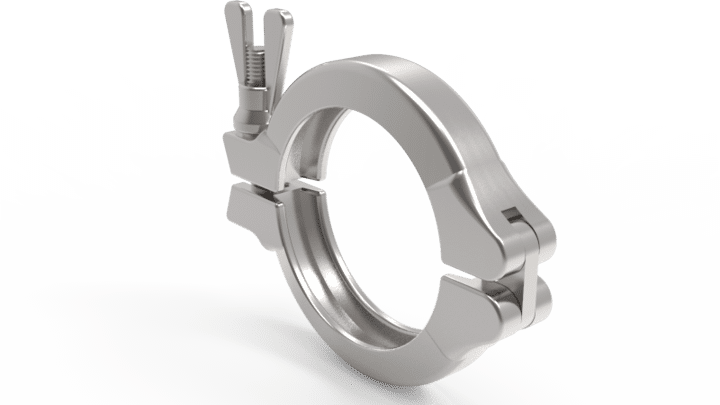

The QCF components and the corresponding VaCFix® tensioning chains enable fast assembly in the UHV range. They combine the sealing principle of the CF flanges (cutting edges according to ISO 3669, ConFlat® compatible) and the simple assembly principle using a tensioning chain.

QCF components can be mounted quickly, easily and at the same time in a space-saving manner and can be connected to all existing vacuum systems by means of adapters. The CF-QCF adapters provide users with the option of using the QCF connection technology on existing UHV systems and thus always remain flexible as well as supplier-independent. The copper seals commonly used on the market can be used for all nominal diameters. The requirements of UHV technology for a leakage rate of < 1.0E-11 mbar l/s and the bake-out capability of the flange connection up to 350 °C are met.

VaCFix® tension chains can also be used for the connection of KF and conical ISO flanges.

The quick connection for HV, UHV and XHV:

- Up to 75 % shorter assembly times are an enormous advantage for flange connections that have to be opened frequently.

- Ideal UHV-compatible quick connection for use in radioactive environments - the use of QCF connections significantly reduces the risk of exposure for assembly personnel.

- QCF flange connections can be mounted in any angular position, just like rotatable flanges.

- Even in tight spaces, VaCFix® tension chains can be mounted quickly and easily.

- QCF components have been successfully tested at operating temperatures from -270 °C to 350 °C by independent institutes.

- VaCFix® tension chains are also excellently suited for the assembly of tension-sensitive flange components such as sight glasses and feedthroughs, as the tension chains ensure a very even contact pressure when using a torque spanner.

- By increasing the torque in a defined way, copper gaskets can be used up to three times.

Comparison of the QCF connection technique with classic CF flange assembly

| Nominal size | QCF | CF | |

Assembly time: | DN16 | 30 s | 180 s |

| DN40 | 30 s | 180 s | |

| DN63 | 40 s | 240 s | |

| DN100 | 80 s | 360 s | |

Space requirement / installation freedom:

| DN16 | 24 mm | 35 mm |

| DN40 | 24 mm | 61 mm | |

| DN63 | 28 mm | 80 mm | |

| DN100 | 41 mm | 90 mm |

Further product details:

- Borehole alignment - swivel / fixed flanges:

QCF flanges have no bolt holes. This eliminates the need to align the bolt circle when welding on. Rotatable flanges are therefore not required. - Sealing principle / sealing medium:

Same sealing principle (ISO 3669) and same standard copper gasket as the classic CF connection. - Independence from flange systems:

By means of QCF-CF adapters, the most suitable connection system for the respective requirements can be used in combination. - Non-magnetic flange connection:

VaCFix® tension chains are non-magnetic. In combination with QCF flanges made of stainless steel 1.4429, a UHV flange connection with a magnetic permeability < 1.005 is created.

Materials

VACOM only uses materials suitable for vacuum applications, such as stainless steels, ceramics or crystals. For demanding vacuum applications, VACOM stocks forged corrosion-resistant stainless steel 1.4429-ESU (316LN ESR). This material, manufactured using the electroslag remelting process (ESU/ESR), is characterised by particular purity and homogeneity, great hardness and very low magnetic permeability. The material is specially manufactured according to VACOM specifications. With regard to composition and purity, VACOM has oriented itself to the state of the art and has defined tolerances that are significantly narrower than those specified in the standard. VACOM ESU steel is subject to VACOM control from the melt to the final product. In addition to stainless steels, VACOM processes a number of other vacuum-suitable materials. These include aluminium, glasses, ceramics, crystals, copper, nickel-based alloys, tantalum and titanium.

Properties of stainless steels used at VACOM:

| Material ASTM | Rp 0.2 (0.2 % proof stress) [N/mm²] | Hardness[HB] | Max. recommended operating temp. [°C] | Magnetic permeability | Corrosion resistance class |

| 1.4301 / 304 | ≥ 190 | ≤ 190 | 450 (842°F) | ≤ 1,3 | II |

| 1.4307 / 304L | ≥ 175 | ≤ 215 | 450 (842°F) | ≤ 1,3 | II |

| 1.4404 / 316L | ≥ 200 | ≤ 215 | 500 (932°F) | ≤ 1,1 | III |

| 1.4429-ESU / 316LN-ESR | ≥ 280 | ≤ 250 | 500 (932°F) | ≤ 1,005 | III |

| 1.4541 / 304Ti | ≥ 190 | ≤ 215 | 450 (842°F) | ≤ 1,3 | II |

| 1.4571 / 316Ti | ≥ 200 | ≤ 215 | 550 (1022°F) | ≤ 1,3 | III |

We will be happy to advise you on material availability, vacuum suitability of materials and processing options.