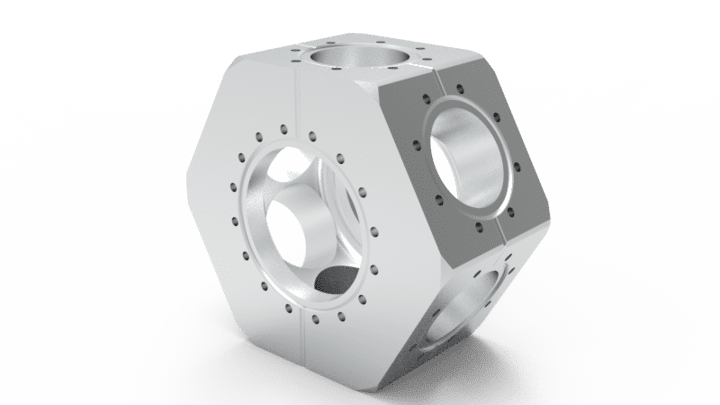

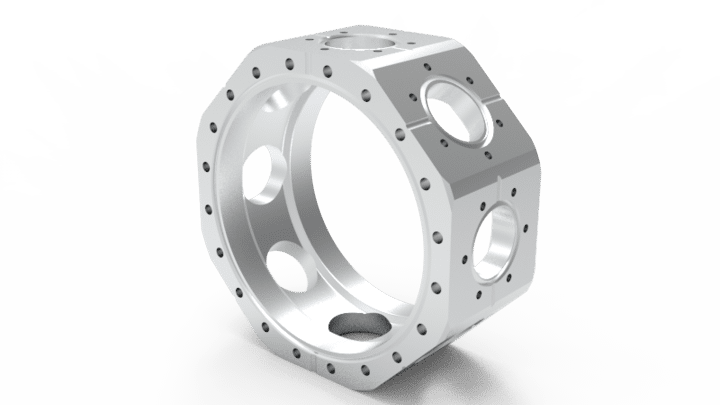

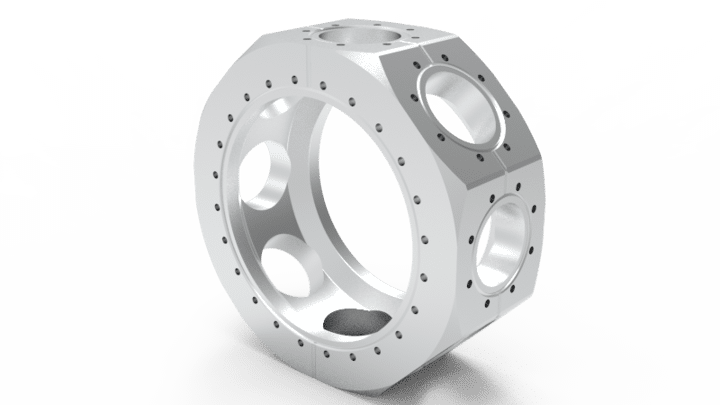

From the vacuum screw to the complete vacuum chamber.

Vacuum Chambers

Requirements for vacuum technology applications, especially in the high-tech sector, go far beyond those of traditional mechanical engineering. A weld seam must be mechanically stable and gas-tight. The materials used must be characterised by low outgassing and low gas permeation. In electropolishing, it is not enough that a bright surface is produced. In the XHV range, every square centimetre of surface is one cm² too many. The difficulty here is to make the design of the vacuum chamber and components as small as possible. However, this leads to new technological challenges due to heat dissipation in the manufacturing process. If, on the one hand, low outgassing and minimal gas permeation are required and, on the other hand, minimal particle generation and affinity, the possibilities become even more limited.

For niche markets such as vacuum technology applications, it is necessary to find and define a suitable interface between the "mass products" available on the market and the highly specialised one-offs. Here it is necessary to understand interrelationships, to question basic physical processes and to develop the ability to work in an interdisciplinary manner.

As an experienced manufacturer of vacuum chambers and special components, we base our design on all these interrelationships and findings, thus achieving new efficiencies and qualities.

Special Vacuum Chambers and Components

VACOM develops and designs customer-specific vacuum chambers and special components for UHV and XHV. The processes are accompanied by a well-organised, highly qualified quality assurance with optimum modern measuring technology.

We offer:

- Vacuum-compatible design, certified welding according to DIN EN ISO 3834-2.

- AluVaC®, CF cutting edges and Dichtflächen milled directly onto chamber walls.

- Alignment of ports to defined focal points

- Guarantee for 100 % leak-free vacuum components.

Excerpt from our catalogue of services:

| Design of components according to customer specifications |

|

| Mechanical manufacturing |

|

| Welding technology |

|

| Surface and component finishing |

|

| UHV-compliant cleaning and baking out |

|

| Quality assurance at VACOM |

|

| Bake-out, assembly and packaging in clean rooms |

|