From the vacuum screw to the complete vacuum chamber.

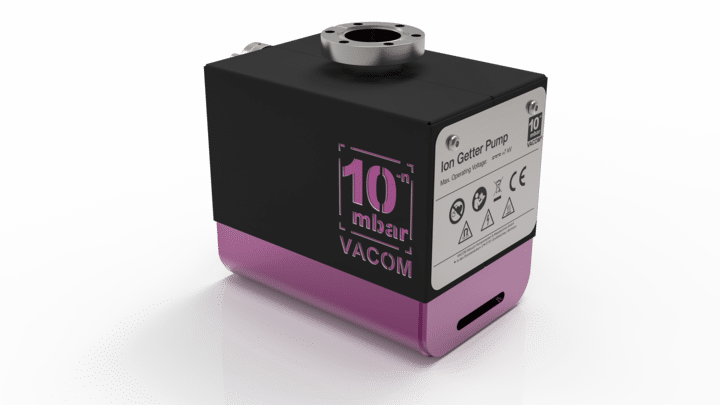

MERKURION® Ion Getter Pump

Ion getter pumps (IGP) are mainly used for vacuum applications with a pressure < 10-5 mbar. Their pumping action is based on a getter layer that is continuously refreshed by means of a gas discharge. This operating principle dispenses with moving parts - so IGPs work completely vibration-free, without failure and with low maintenance. They are ideal for closed systems that require a permanently reliable and deep vacuum. The discharge current is proportional to the working pressure. On the one hand, this effect allows the pump to be used as a coarse pressure gauge, and on the other hand, it allows very low energy consumption at low pressure. IGPs thus offer a clean and inexpensive method of achieving and maintaining extreme vacuum environments.

VACOM takes ion getter pump technology to a new level with the MERKURION series. Our IGPs offer a clean and cost-effective way to achieve and efficiently maintain pressure ranges from high vacuum to extremely high vacuum. With the range of different flange connections and pump sizes, easy integration into your existing systems is made possible. The optionally integrable heater, in combination with the built-in temperature shield, ensures an even temperature distribution over the entire pump. Particularly worthy of mention are our pumps of the pro series, which can be heated without any additional insulation measures (e.g. aluminium foil). For pumping noble gases, we also offer our pro series with a noble gas-stabilised differential pumping element (Ta/Ti Noble diode).

Technical Data

| MERKURION® pro | MERKURION® basic | |

| Pumping element | Diode | Noble Diode | Diode |

| Stable for noble gases | Yes, with variation of the Noble Diode | No |

| Operating Life | 70.000 h bei 1 × 10-6 mbar | 50.000 h bei 1 × 10-6 mbar |

| Delivery state | ·cleaned (PC 2 & UHV 1) ·under vacuum ·factory function test | Under vacuum |

| Nominal pumping speed | From 39 l / s to 68 l / s | From 3 l / s to 300 l / s |

Choose your complete IGP package and you are ready to go. We offer two different operating units to get the best performance from your ion getter pump. Operation is intuitive and simple, via buttons or touch screen. In addition, data exchange via interface is also possible. Call up all relevant information via the display and, if required, have it shown as a graphical diagram view. Of course, you can also obtain bakeable cables with safety interlock (SAFECONN) from us. We offer comprehensive, competent advice and are always available to answer any questions you may have about MERKURION®.

Typical applications

The list of applications for IGP is extremely diverse. They form an integral part of scientific instruments, for example in accelerator physics, mass spectrometry and surface analysis. Furthermore, the manufacture of vacuum tubes, the development and production of semiconductor elements, space simulation and many other areas require the use of IGP. Here, the application in electron microscopy and electron beam lithography should be mentioned in particular. Despite the relatively high pressures common there, IGP are indispensable for these applications due to their absolute freedom from vibration.

Functionality of diode ion getter pumps

An IGP of the diode type consists of one or more pump elements (depending on the pumping speed), the associated external iron yoke with permanent magnets and the pump housing. The pump elements perform the actual pumping work. Each pump element consists of a solid composite of two cathode sheets and an anode element (called anode for short), whereby these are electrically insulated from each other by ceramic insulators.

The anode is made up of numerous short tubes that are placed together like honeycombs. Each tube forms the centre of a Penning cell. The anode is located between the two cathode sheets, which are separated from the anode by a gap in which the residual gas particles can fall in a vacuum to be "pumped out".

The more cells the pumping element contains, the higher the pumping speed. One or more pump elements are installed in the pump housing. The pump housing is in itself a small vacuum chamber that has pockets to hold the pump elements. The permanent magnets are placed on the pockets from the outside and complete the construction with the iron yoke.

The pumping action of an IGP is based on the following phases:

- generation of an electron cloud

- ionisation of the gas molecules

- ion impact and release of reactive cathode material

- binding of gas particles and neutralised ions