Experiments in particle accelerators show it.

Accelerator

With their large system dimensions and low pressures, particle accelerators are among the most demanding vacuum applications in the world. The diverse experiments and applications in the field of particle physics place the highest demands on the quality of the vacuum and thus on the vacuum technology used. In cooperation with you, we face the challenge of pushing the limits of vacuum technology.

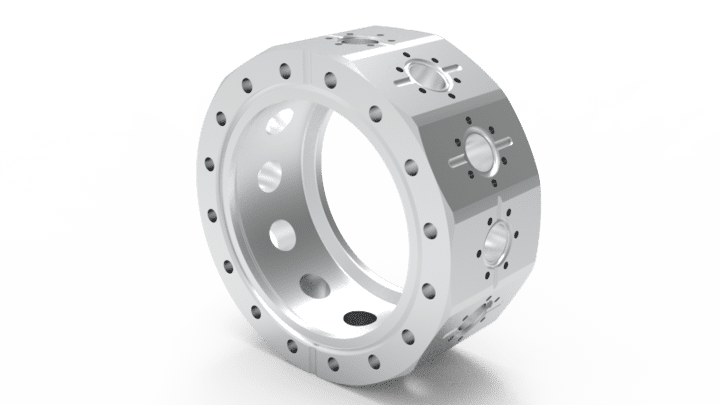

VACOM serves these high-end applications with components suitable for UHV and XHV, which have been optimised for use in particle accelerators in terms of material selection and surface cleanliness. You can rely on our components made of special stainless steel alloy 1.4429-ESU with reduced magnetic permeability of only µr < 1.005. You can also benefit from vacuum components made of aluminium from the AluVaC® series with an even lower outgassing rate and lowest magnetic permeability of µr = 1.00002. With the VaCFix® quick-clamping system, you can assemble your components more quickly and easily than with the usual multiple screw connections; in addition, you can install system components in an even smaller space thanks to the compact flange system.

We offer:

- defined cleanliness and outgassing parameters of our vacuum products through our VACOM® Purity Classes and VACOM® Vacuum Classes

- lightweight aluminium CF components of AluVaC®technology with optimised outgassing behaviour and lowest magnetic permeability

- ion getter pumps of the MERKURION® series provide efficient pumping speed in different versions available

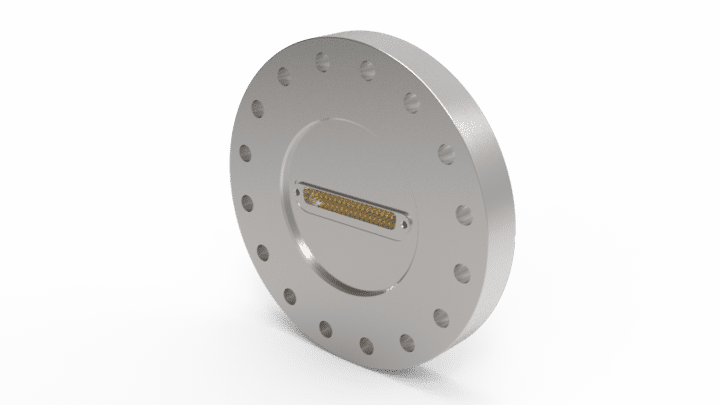

- optical fibre feedthroughs and electrical feedthroughs for UHV applications

- construction and high-precision machining of your individual special components and chambers