From the vacuum screw to the complete vacuum chamber.

Aluminium and AluVaC® Technologies

With AluVaC® technology, VACOM produces high-quality, durable and bakeable aluminium components with CF cutting edges. Rely on the advantages of aluminium. The components are lightweight, extremely low in outgassing and have low magnetic permeability. Tests have proven the long-term stability of the cutting edges. You will find components and parts made of AluVaC® in a wide range of product groups.

Industrial processes, scientific fields as well as research and development such as in accelerator technology or EUV technology increasingly require clean and better ultra-high vacuum (UHV, p < 1 · 10-07 mbar = 7.5 · 10-8 Torr) or extreme high vacuum (XHV, p < 1 · 10-11 mbar = 7.5 · 10-12 Torr). Stainless steel solutions are reaching their limits, making them more time-, energy- and cost-intensive. Aluminium presents itself as the material of the future. It may become the material of the future, especially in chamber construction for the UHV and XHV range, because, for example, it is possible to reduce costs with ease. The stable long-term use has been proven by long-term in-house tests. Many companies, institutes and users now use our AluVaC® components.

AluVaC®– CF components and vacuum chambers made of 100 % aluminium

All AluVaC® components are compatible with CF stainless steel components. Especially for vacuum applications in the low pressure ranges of UHV and XHV, aluminium offers advantageous product properties compared to stainless steel:

- Lower natural material outgassing: qA < 2 · 10-14 mbar⋅l⋅ s-1⋅cm-2.

- More energy-efficient bake-out at temperatures of 120°C (compare 200 - 450 °C for stainless steels) = 248°F (compare 392 - 842°F)

- Enables more time-efficient work due to faster pump-down times

- Production of components with low magnetic permeability (µr = 1.00002)

- Advantages in handling due to minimal weight

High-quality, durable and bakeable aluminium components with CF cutting edges

VACOM manufactures CF connections exclusively from aluminium alloys, without additional coating or a stainless steel component. The mechanical strength of 6xxx- aluminium alloys is suitable for long-term stable CF cutting edges according to ISO-3669 with the use of soft-annealed copper seals. Even the 120°C (248°F) required for annealing does not affect the cutting edge stability. Tests have shown that the extremely low-outgassing AluVaC® components retain their functionality even under short-term thermal loads up to peak temperatures of 180°C (356°F).

Many products with AluVaC® technology

Due to its excellent material and manufacturing properties, aluminium provides the prerequisite for a wide range of vacuum applications.

Since the introduction of our AluVaC® series, our standard and special component portfolio has been growing continuously. Customers benefit from our extensive range and many years of experience in the design, production and cleaning of aluminium components. Depending on the requirements, our aluminium components and chambers can be cleaned according to VACOM® Purity Classes and classified according to VACOM® Vacuum Classes.

Advantages of aluminium compared to stainless steels:

- extremely low outgassing rates due to the use of aluminium

- more compact design possible / more outlets on surfaces realisable

- low magnetic permeability µr = 1.00002 and homogeneous temperature distribution

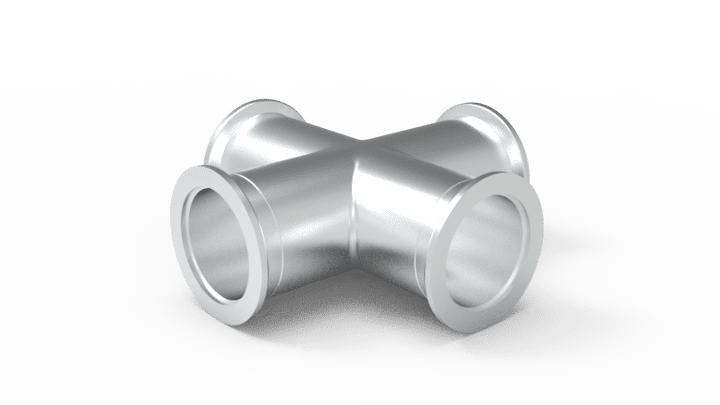

Standard components made of aluminium

Our product range includes an extensive assortment of aluminium components. We offer KF, ISO and CF components (AluVaC®) made of high-quality 6xxxx aluminium alloys.

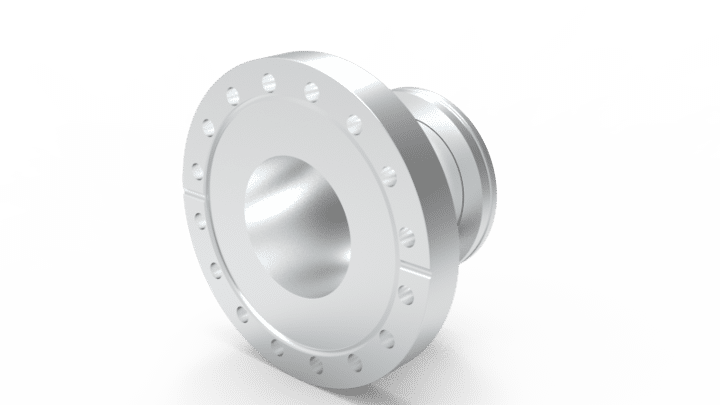

Aluminium optical components with CF cutting edge (AluVaC® - High Precision Optics)

In the field of vacuum optics we have developed the first products made of aluminium with CF cutting edge and included them in our portfolio. With our AluVaC® Precision Optics you get optical precision made of aluminium. Especially for laser- UV-VIS or wide range applications our products are perfectly suited. For more information on sight glasses made of aluminium, please click here.

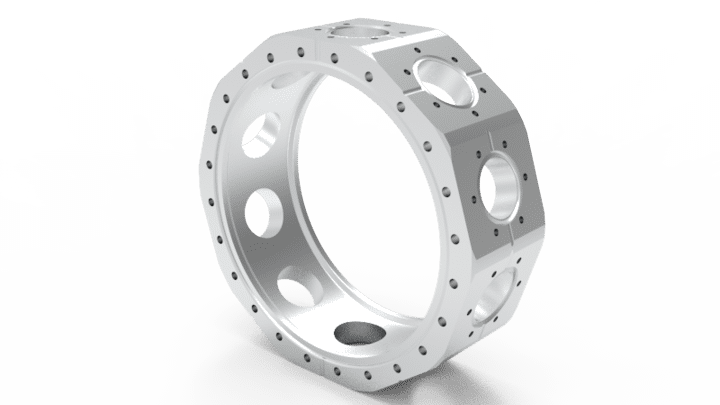

Special components - welded and milled parts made of aluminium

We offer you comprehensive advice, design suitable for cleaning and manufacture of your individual aluminium component. Our latest aluminium chambers convince with their excellent material properties and their uniqueness in chamber design.

Flexibility in chamber design through AluVaC® technology

Compared to stainless steels, the machining of aluminium can be far more time and cost efficient. Already in the design phase, complex welded assemblies can be designed as purely machined components. In addition, there are further advantages:

- exclusively machining tolerances

- elimination of welding tolerances

- extremely low outgassing rates due to the use of aluminium

- more compact design / more outlets on surfaces realisable

- no distortion due to low hydrogen annealing (in situ bake-out 120°C = 248°F is sufficient for aluminium)